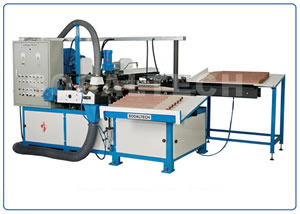

FULLY AUTOMATIC SQUARE DRUM PRODUCTION LINE, MODEL – SSDM 600 |

||

| Objective | To make Square or Rectangular drums using relevant mandrels and raw materials etc | |

| Sizes of the products made | Minimum Inner size – 300 x 300 mm Maximum Inner size – 400 x 400mm Minimum height : 300mm Maximum height : 700mm Minimum wall thickness : 2mm Maximum wall thickness : 4mm |

|

| Output of the main winder | Upto 2000 drums per day depending on the sizes and raw materials used | |

|

List of machines Used |

Sodaltech Convolute type Automatic Body making machine – 01 No

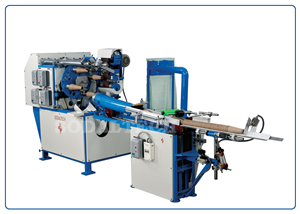

Lid forming & Pasting machine with Hydraulic system and power pack with one standard size toolings – 1 No Size Reduction machine with Hydraulic system and power pack with one standard size toolings – 01 No Air Compressor 10 Hp Capacity with storage tank (Customer Scope) |

|

| Space Requirement | Not less than 500 Sq.Mt (or) 5000 Sq.Feet | |

| Godown Requirement | 300 Sq. Mt (or) 3000 Sq.Feet depending on the plan | |

| Power Connection | 20 KW (Excluding Air Compressor and lighting etc) | |

| Operator | Main Machine – 1 No Finishing machine – 4 Nos Helpers as per the work plan at the site |

|

| Raw Material Used | Kraft Paper of 250 GSM , Not less than 14 BF Width : As per the drum sizes Glue : Polymer based (or) Starch based glue as per the end product requirement |

|

| Principle of Operation | You can visit the following link https://drive.google.com/file/d/1EGeFb4VBmltdFywW5WNU4LaaK1GdrrnS/view for main winder operation. The drums are provided with plastic lid (or) paper lid as per the requirement using the Semi Automatic Drum finishing machines. |

|

NOTE

The production capacity indicated above is only approximate and does not include any tool changing times or similar. The production efficiency and the output figures may vary in practical operation according to sizes of the products, operator efficiency, weather etc.